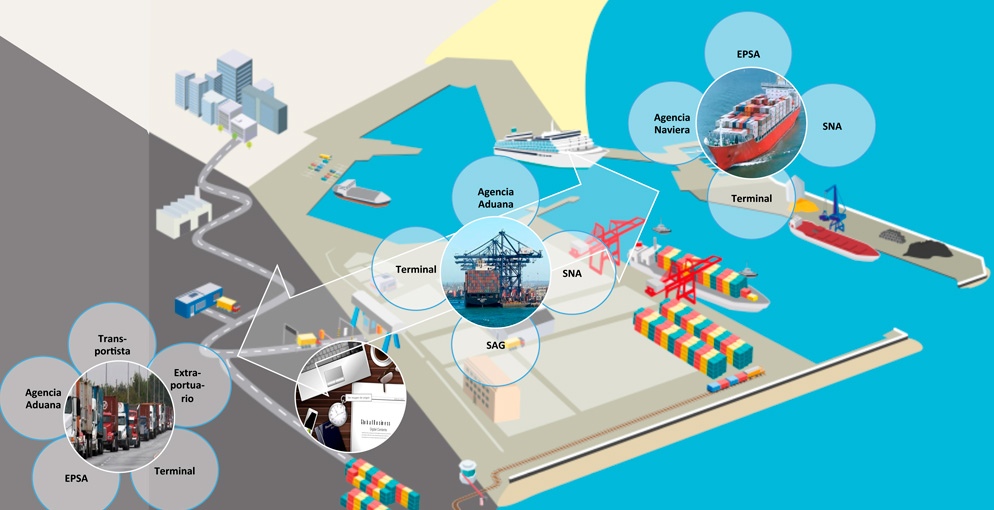

Modelling and analysis of logistics chain processes for containers, bulk cargo and vehicles using the BPMN (Business Process Management Notation) tool, Bizagi Modeler. This modelling identified both the physical and documentary flows generated between stakeholders that enable the passage of goods through the Port of San Antonio in Chile. Having modelled the logistics processes, simulations were carried out on future traffic for 2020 and 2025 to detect bottlenecks and propose process redesign and improvement solutions linked to proposals to eliminate paper, thereby helping to leverage investment in the development of a PCS (Port Community System) platform.

Identification of improvement proposals for the optimization of the port logistics chain for the Port of San Antonio (Chile). These proposals cover the incorporation of new procedures, business rules, regulation elements (location or other); technology implementation through information systems such as PCS (Port Community System), hardware platform for running services linked to the systems, technological elements for automatic data capture, identification of all necessary interactions for the integration of processes between companies, as well as improvements to the configuration of sites where the activities linked to the aforementioned processes are carried out; and lastly, business models to enable the operation of said technology platforms and sites where logistics activities are carried out.

The key activities carried out in the project were the following:

- Establishing operational, documentary (or information) flows and the physical locations where the activities of each logistics line are carried out.

- Considering the different means of ground transport (railway and road) of the logistics chains.

- Establishing the specific characteristics of the processes for different types of cargo (specifically types of packaging or another).

- Description of the systematized or non-systematized documentary flows relating to movement of cargo, which are generated for each stage of the overall process of export, import and transit.

- Validation of the survey of the physical and documentary flows in the port logistics chain, with stakeholders (public and private sector) validating the stages they are involved in.

- Field surveys of process information (when required for relevant samples).

- Determining the services that entail an added cost for each process.

- Determining the process distribution functions or rates.

- Mathematical modelling of processes.

- Identification of the main process bottlenecks (using mathematical modelling and stakeholders’ perceptions collected through interviews).

- Identification of short, medium and long-term improvement opportunities, according to the findings from the preceding points.

- Establishing the redesign proposals needed to achieve the best operational configuration for the logistics of the San Antonio Port System.