The objective of the project was to estimate the capacity of the Terminal Cuenca de Plata (TCP) of the Port of Montevideo. The capacity of a port facility can be defined as the maximum volume of traffic (measured in tons, containers, TEUs, or units) that it can handle in a given period and scenario (boundary conditions). As such, the exact definition of port capacity has not been decisively established. Since the conditions or scenarios in which the maximum can be calculated may vary, there are different concepts of capacity.

Carrying out this study helped provide the TCP with a depiction of the situation of the terminal at that moment in terms of port capacity, thereby helping it to anticipate the actions the company had to implement and the available opportunities in possible future scenarios. Consequently, this study helped the TCP to achieve its goal; namely, to “transform the company into the main logistic support for the region’s maritime transport, integrating the Terminal in the international distribution chain through its ties with Katoen Natie”.

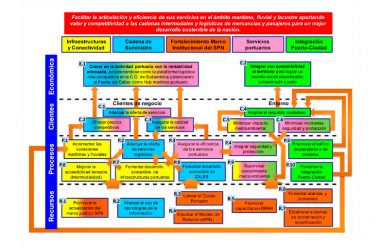

This Technical Assistance project involved three main objectives:

- Determine the maximum traffic that can be handled by the terminal in operation.

- Provide a planning aid tool.

- Possible analysis of future improvements (expansion or reallocation of use in an existing facility), supporting decision-making.

There were various boundary conditions for the calculation of the capacity—conditions linked to the economic optimization of the facilities:

- those determined by the saturation of the facilities;

- and those corresponding to the minimum permissible quality of service received by customers, since an increase in traffic reduces the quality of the service received by terminal customers.

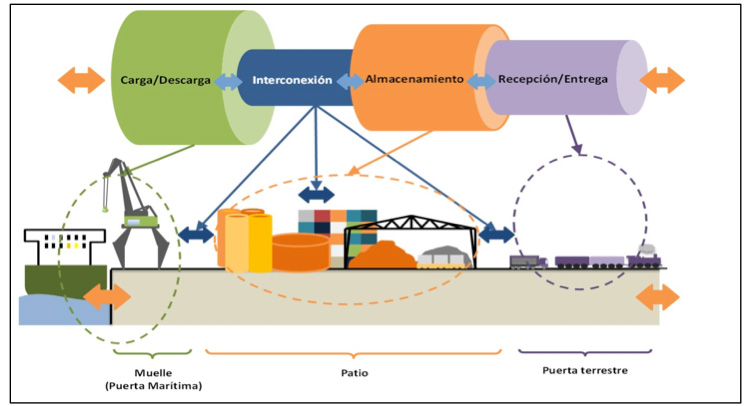

The method used to calculate port capacity accounts for the systemic design of a container terminal composed of four subsystems:

Based on a simplified analytical view, a series of working hypotheses were generated that allowed each subsystem to be addressed in isolation.

From a planning perspective, neither the interconnection subsystem nor the reception and delivery subsystem should be a limiting factor for capacity, assuming that these are sufficiently well equipped to prevent bottlenecks:

- Interconnection subsystem: since there is sufficient interconnection equipment to carry out the work such that it does not delay the activity of the quay crane or the yard equipment, it is therefore assumed that this cannot be a limiting factor for terminal capacity.

- Reception and delivery subsystem:

- External trucks: the access flow depends on the number of gates, operating hours, and the time required for the entry/exit operation.

- Rail: it is assumed that the terminal has enough routes to handle the incoming and outgoing freight traffic

BERTH CAPACITY

Several aspects were taken into account when calculating berth capacity, including:

- Statistical distribution of ship arrivals.

- Ship characteristics (length, draught and stowage height on board).

- Characterization of berth lines (length and depth of the berths).

- Statistical distribution of service times.

- Number and productivity of berth equipment.

- Permissible level of quality associated with wait times.

- Operation time of the terminal per year.

A hybrid methodology was used in this study to calculate berth capacity: analytical calculation combined with simulation for the subsystem in question.

In the analysis of the capacity of the ship loading and unloading subsystem, two different operations were identified: the berthing operation and the loading/unloading of the ship. The annual berth capacity can be obtained by multiplying the number of docking stations by the berth occupancy rate, the annual operating hours, and the average hourly production of ships during their berthing.

For the detailed analysis of the berth capacity using analytical and simulation methods, it was necessary to determine the distribution of ship arrivals and the distribution of terminal service times.

STORAGE CAPACITY

This task involved an analysis of the storage capacity, or capacity by area, of the TCP. In other words, this task was aimed at determining the maximum traffic that can be handled given the storage area of the terminal. The following aspects were taken into account in this analysis:

- Surface density and productivity of the container storage system.

- Stacking height

- Length of stay of freight in the terminal.

- The seasonality of traffic.

- The layout of the terminal floor.

- Yard management (operating system employed).

RESULTS:

- Characterization of existing infrastructure, superstructures, operations and services at the TPC.

- Characterization of TCP subsystems.

- Calculation of the capacity and analysis of the service level of the TCP.