The development of the project included the design and analysis of a fully automated solution for the operation of an empty container depot in the Riba-Roja Logistics Park:

- Review of automated container handling solutions offered by major manufacturers of this type of machinery.

- Structured analysis of functions, services, processes and operations carried out in empty container depots.

- Design of an innovative automated solution, tailored to the operational needs of container depots and to the spaces in the new Riba-Roja Logistics Park; a solution that can be transferred to other locations and container depots.

- Selection of machinery/technology and notable suppliers;

- Layout design

- Considerations relating to the different activities of the container depot: loading-unloading process; container storage; inspection process; additional services; public works

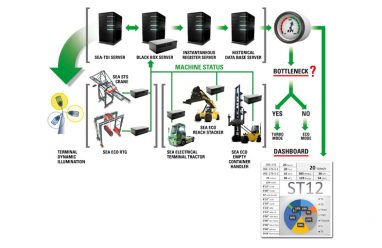

- Software considerations—features and specifications of the management system

- Simulation of the chosen solution and key operating parameters or indicators

- Schedule for implementation

- Economic and financial analysis for the subsequent implementation of the project

- Dissemination of the results among the group of companies dedicated to the activity of container depots in the area surrounding the Port of Valencia.

The proposed solution for the new automated container depot is based on the innovative system of ZPMC (Shanghai Zhenhua Port Machinery), the world’s leading manufacturer of container terminal cranes, for an automated container storage area. The company’s first prototype is operating in the Wai Gao Qiao terminal in Shanghai (China).

The system consists of two types of RMGs operating in an integrated and fully automated way: one for movements within the storage area, and another for external movements (loading and unloading of trucks; positioning for inspection and workshop). Between the two are intermediate transfer zones, specially designed to enable the required intermediate operations, such as inspection, to be carried out safely. Similarly, an intermediate zone has been designed to connect the storage area with the workshop area and complementary activities (washing, pretrip, etc.) through horizontal carts.